/Products/Steels for quenching, tempering and case hardening

STEELS FOR QUENCHING, TEMPERING AND CASE HARDENING

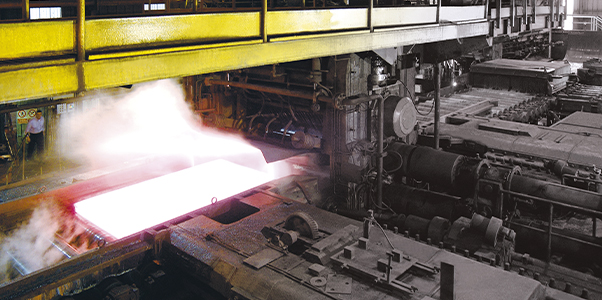

Tempering is a process of heat treating, which is used to increase the toughness of steel. Tempering is usually performed after hardening, to reduce some of the excess hardness, and is done by heating the metal to some temperature below the critical point for a certain period of time, then allowing it to cool in still air.

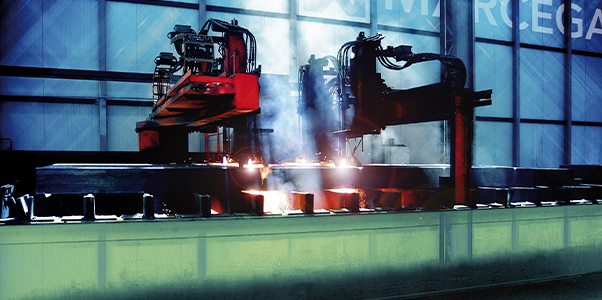

Quenching is the rapid cooling of a workpiece to obtain certain material properties. The exact temperature determines the amount of hardness removed, and depends on both the specific composition of the alloy and on the desired properties in the finished product. For instance, very hard tools are often tempered at low temperatures, while springs are tempered to much higher temperatures.

Steels for Q.& T. are for a variety of mechanical uses and fabrications such as gears, shaft, bolts, ratchets and buckets.

| MANUFACTURING STANDARD |

|

| EN 683-1 | Steels for quenching & tempering – non alloyed steels |

| EN 683-2 | Steels for quenching & tempering |

| EN 683-3 | Case hardening steel |