PRODUCTION LINES

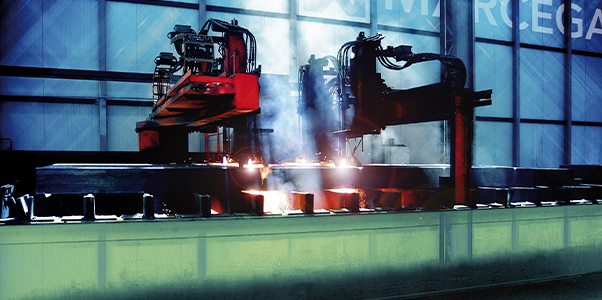

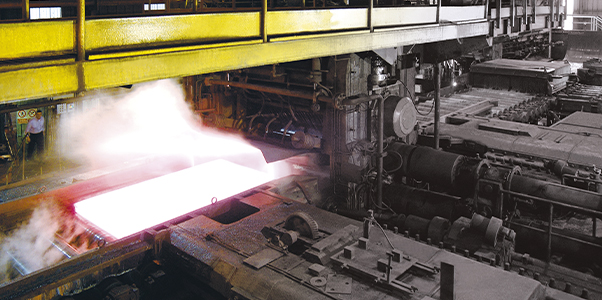

The rolling processes start with slab barcoding (for full product traceability), followed by its cutting and pre-heating treatment into the new pre heating furnace. A part of the 1 million tons globally processed every year is transferred to the internal service centers for cuttings. The other part is set aside for thermic treatments such as soft annealing and/or normalization, which can be run both on line, while rolling under specific temperature controls, or in furnace. These plates are usually designated as high grades and for specific final application purposes.

The service centers are also equipped with a shot-blasting machines (Sa. 2.5) which give plates perfect finishing surfaces cleaned from mill scale, oxides and rust. This mechanical treatment involves shooting a high-pressure stream of steel grits onto the surface making it smooth and ready for final applications like primers, paintings or welding.